ENERGY RECOVERY SYSTEM

Energy recovery in bread making factories has become a necessity because of the increasing costs of the combustibles used. Achieving of a higher thermal efficiency for technological processes in all Romanian industries and not only, occupies an important place on the priority list. It is a well-known fact that approximately 10 – 12% of the energy used for oven heating, thermal central units and others, is thrown away on the evacuation system for burn gas. Even so, the energy recovery is very little implemented in manufacturing industries.

The usual approach in oven/ industrial boiler manufacturing, is to choose the equipment's overall selling price over beneficiary operating costs, which has in consequence, the systematical choice of a cheaper manufacturing solution than an optimal one. In this case, the resulting burnt gases will be evacuated with higher temperatures and none recycled. Therefore, the initial cost of the equipment is lower, but the operating costs (e.g. fuel consumption) are higher, and occupy an important place in the overall economy.

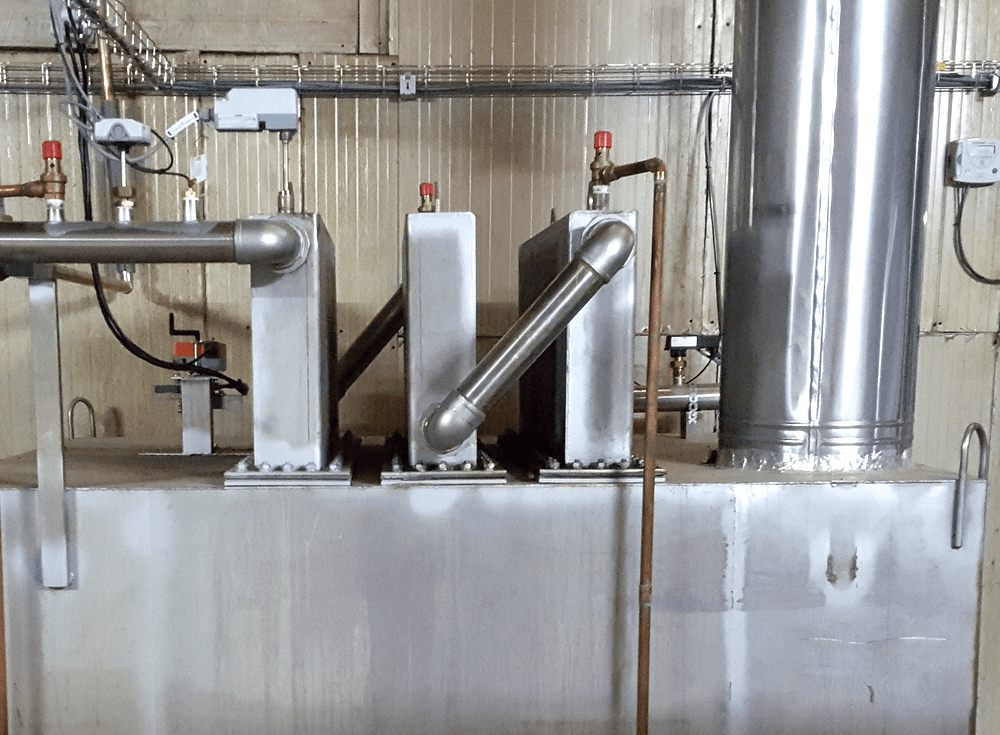

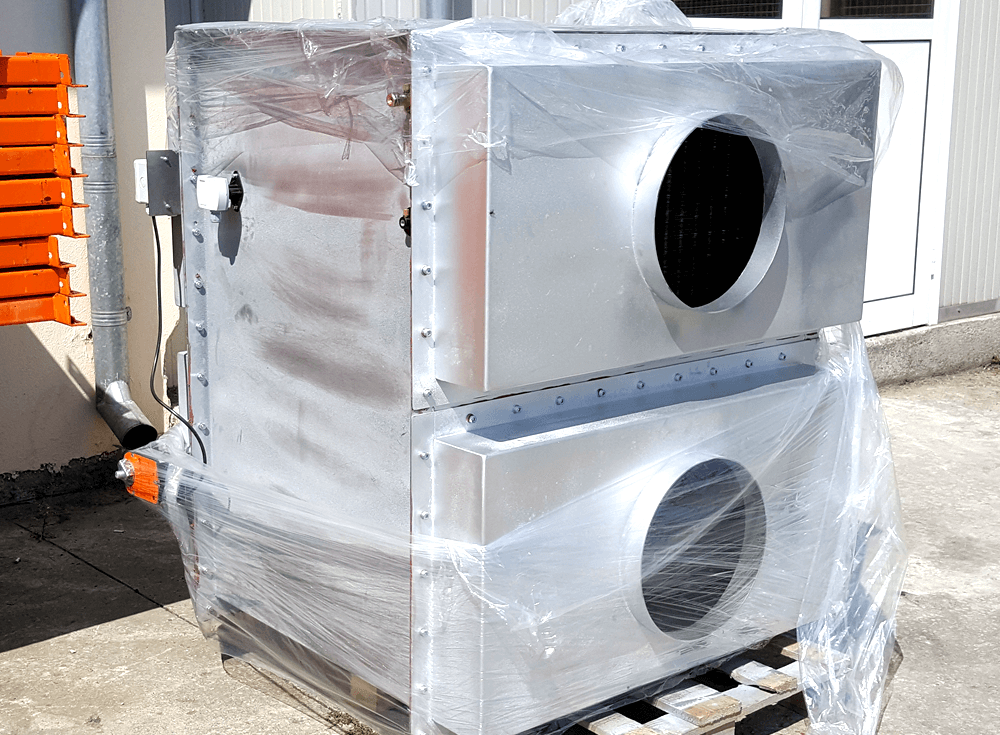

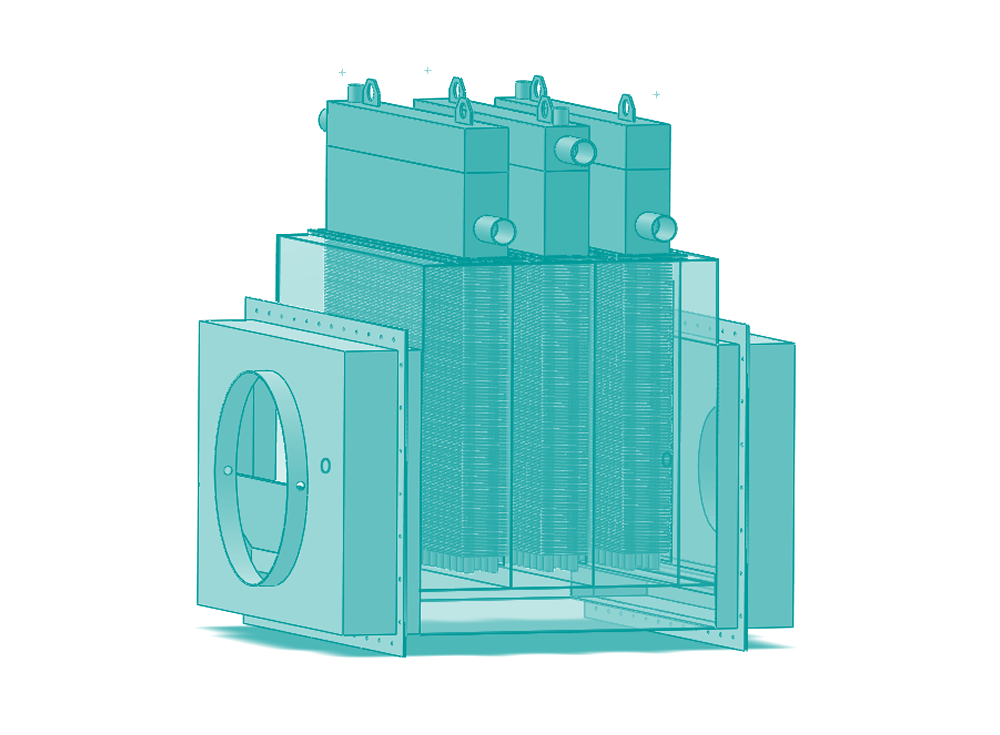

The recovery energy systems with thermal tubes, produced by BioThnologiCreativ Company, are the most performant recovery energy systems available on the market today. These are Gas – Water and Gas – Gas type and can be implemented on all types of gas evacuation systems of the bread baking ovens and steam/hot water generators. The recovery systems can raise the energy efficiency of ovens and generators from 88% - 90% to 99%. The recovery systems produced by BTC, recover between 50 kW/h and 100 kW/h, depending on the installed nominal thermal power.

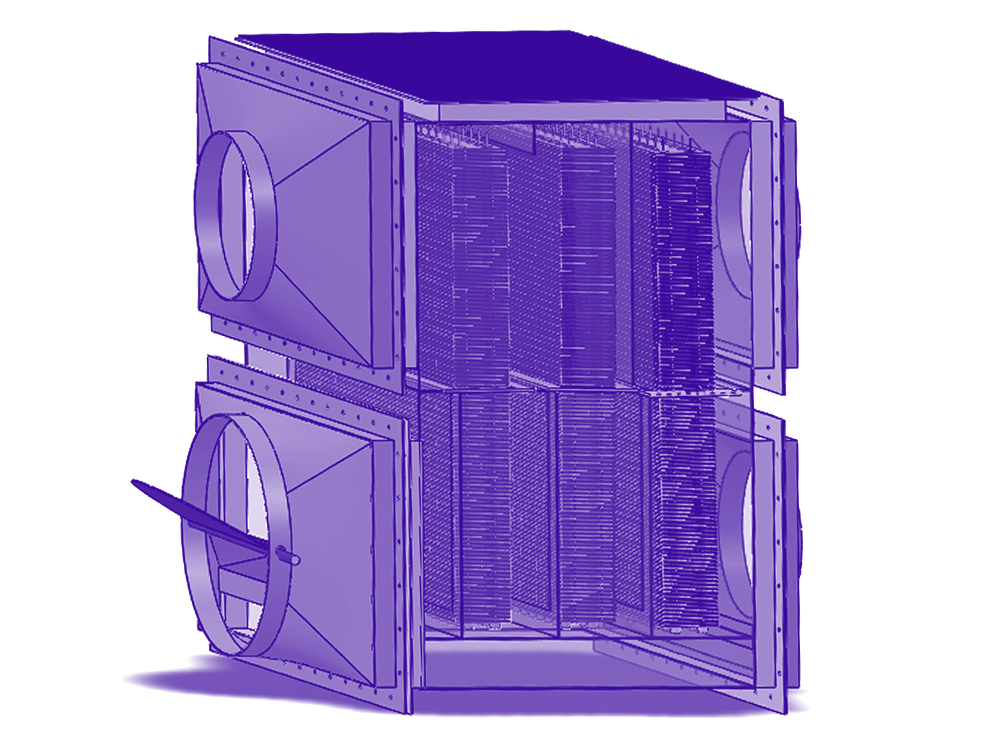

BTC uses the most advanced technology of this field, which is the energy recovery from the burnt gases, using thermal tubes, with high energy transfer performance and multiple advantages: low pressure losses, high reliability and corrosion resistance, do not require maintenance and additional energy and do not have mechanical components in relative movement to each other.

THE USE OF HEAT EXCHANGER WITH THERMAL TUBES IN RECOVERY ENERGY FIELD IN THE BREAD MAKING FACTORIES HAS MULTIPLE APPLICATIONS, SUCH AS:

- - Heating provers;

- - Preheating of water for steam boilers or water heating installation;

- - Heating of production areas, storage units, offices, etc.;

- - Heating of water for domestic usage.

The energy recovery systems produced by BTC are two types: Gas –Air and Gas – Water, with the possibility to heat also water and air. The central units are manufactured with highly durable materials, with great resistance to corrosion: cupper, aluminum and steel.

THE TECHNICAL ADVANTAGES OF THE SOLUTIONS PROPOSED BY BTC FOR ENERGETICALLY OPTIMIZATION ARE:

- The tubes heads are clear, and the tubes expansions are controlled;

- The fluid inside the tube cannot enter in the burn gases thanks to perfect seal between the two mediums;

- Inside the tubes, there are no deposits because the primary and the secondary agents circulate outside the tubes;

- The pressure loss is very small and does not influence the evacuation of the burnt gases outside the oven, thanks to the distribution of air circulation inside the energy recovery system;

- Due to the perfect seal between the two mediums, there is no possibility of forming acid dew inside the evacuation system for burnt gases;

- The energetically efficiency remains unchanged for the entire period of exploitation of the energy recovery system;

- Exploitation and maintenance of this system requires very low costs.

Send a request