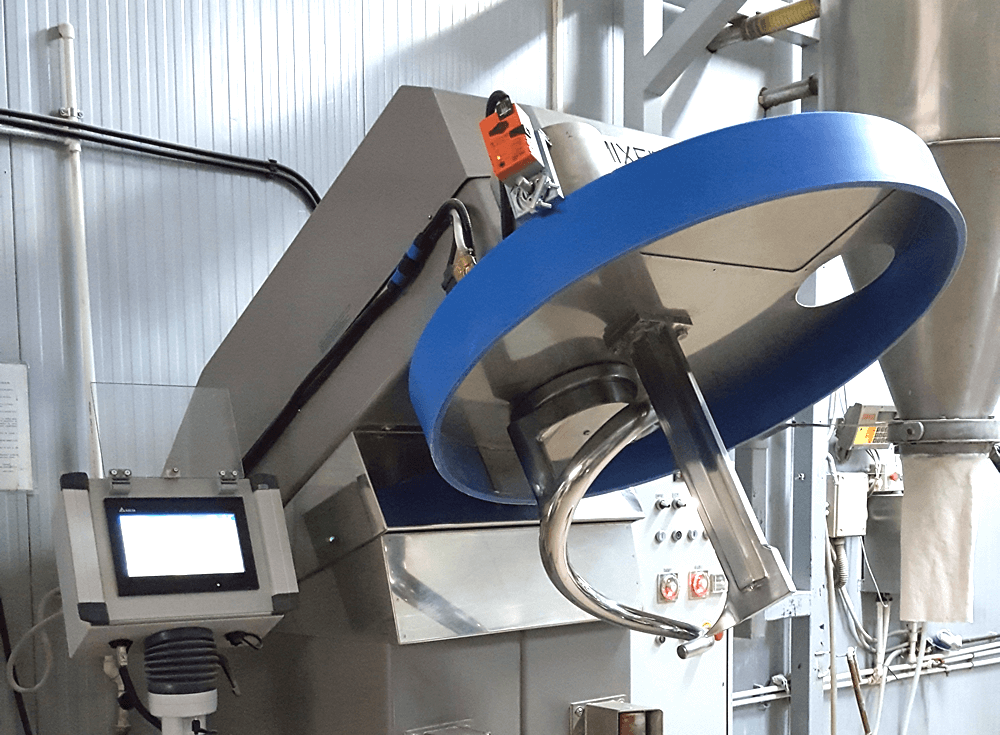

System for the optimization of bread dough kneading process

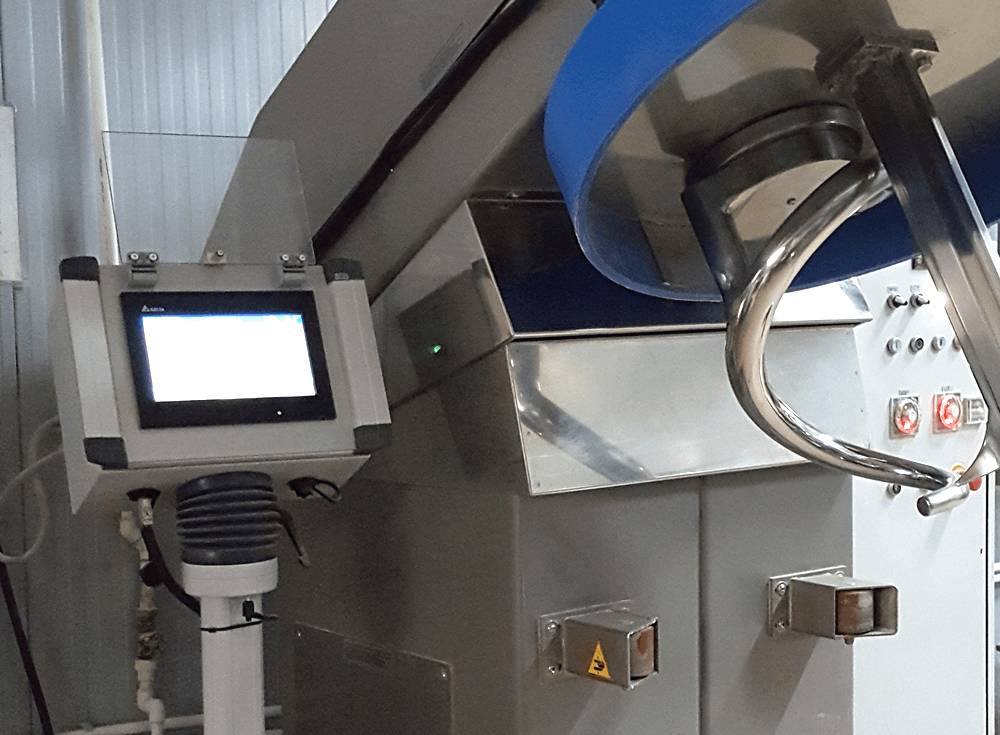

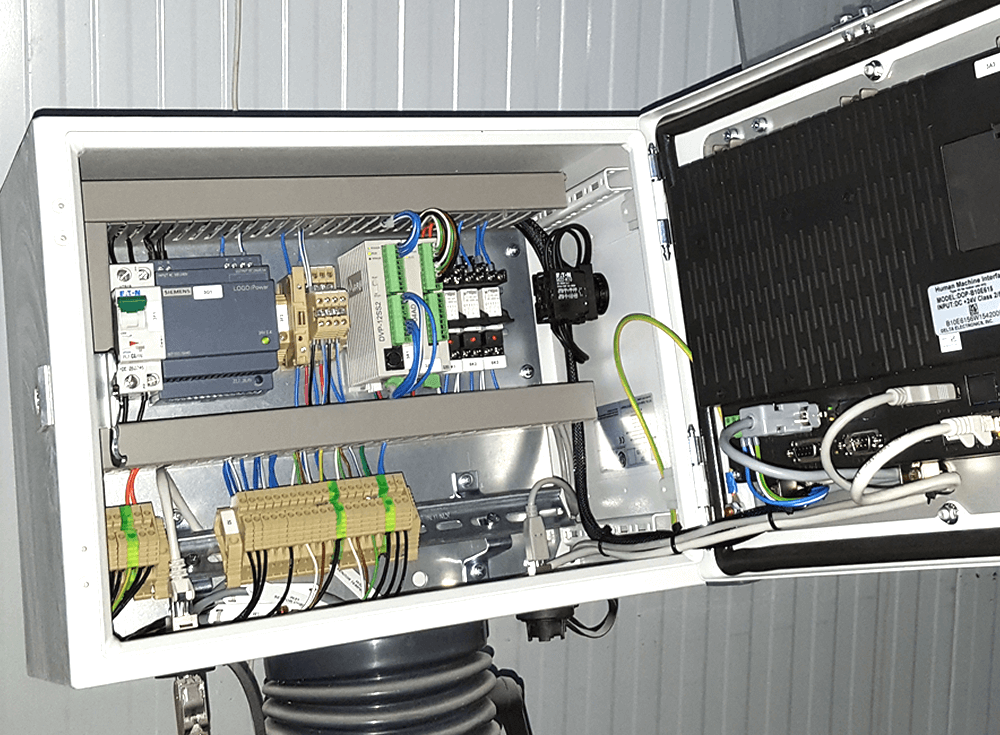

BioTehnologiCreativ Company offers consulting services regarding technical and technological problems in the bread making industry, optimizes technological processes and automating technical processes meeting current market needs with an innovative system for optimizing and controlling the bread dough kneading (SOPF), applicable to any type of kneader.

It is important to have a clear picture of the kneading process, because it shows optimal dough development indicators (gas retention, elasticity / extensibility, behavior in dividing and shaping), which will decide in the next stages of the manufacturing process the quality of the finished product.

Extremely important is the quantity of added water, reported to flours used in the bread making process and which is mainly influenced by the type of kneading (classic or intensive) and by the shape of the kneading arms, or more precisely, by the specific energy introduced into the dough. [J/kg].

In most current kneading processes, dough consistency is organoleptically measured, (even though it is a particularly important property for the entire bread making process and the quality of the finished product). The system for kneading process control and optimization stabilizes the bread making process by ensuring the uniformity of dough consistency in all batches, resulting in similarly qualitative products.

Therefore, errors in the manufacturing process are eliminated (e.g. lower quality doughs with sticky effects, different fermentation). This issues would lead to blockages on the production line.

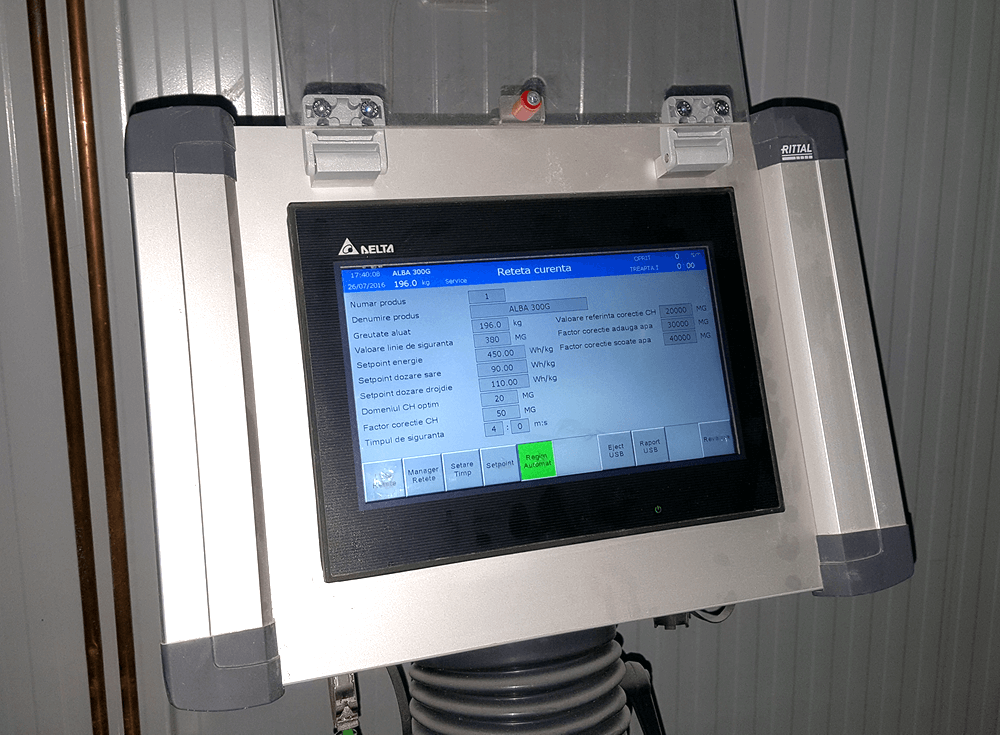

In order to obtain the same consistency for each batch of dough, regardless of the hydration capacity of the flour, the SOPF system indicates the optimal quantity of water, reported to flour. This is the result of an entire analysis of the bread making process, necessary for establishing the minimal dough consistency accepted by the technical production line. The SOPF system is individualized and optimized for every specific technological process.

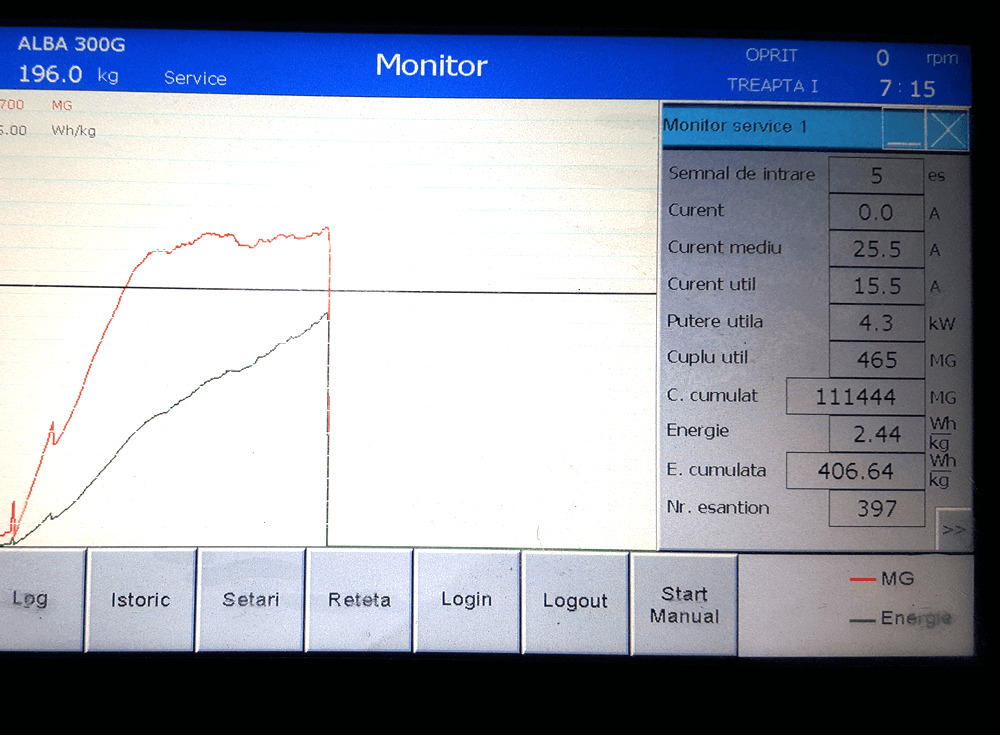

The SOPF system monitors the kneading process and increases the amount of added water to the dough, by accurately indicating it, but also by controlling the specific energy input which develops the gluten network. The SOPF system automatically stops the kneading process if the dough reaches a safe value for dough consistency under which, the dough could not be used in the next steps of the bread making process.

The system also has the ability to perform an analysis to determine the optimal amount of water that can be added to the flour (tested) based on a dough kneading test, only valid for the manufacturing line where it is mounted.

The SOPF system is a completely new approach, both nationally and internationally, being the result of a three year research project. Presently, the system is installed in Romanian bread making factories, where it successfully controls the kneading processes.

FUNCTIONS

1. INTELLIGENT UNIT FOR DOUGH KNEADING CONTROL:

- Monitors the kneading process: determines the optimal consistency of dough in which the maximum quantity of water was introduced without affecting the technological process;

- Stops the kneading process when the set specific energy is reached;

- Shows real time consistency diagram in the form of a single line;

- Stops the kneading process if the value for minimum consistency is reached (which will negatively influence the entire bread making process).

2. TWO OUTPUT SIGNALS WHICH ARE CONTROLLED BY THE SOPF SYSTEM:

- At a specific energy introduced into the dough, the SOPF system commands the opening/ closing of two discharge flaps, etc. The discharge time can differ from one type of flour to another.

3. METHOD FOR THE OPTIMAL FLOUR'S HYDRATION CAPACITY:

- The system identifies the quantity and quality of gluten in each batch of flour being used and indicates the optimal quantity of water which can be added to the mix.

- For this determination, each change in flour type requires the standard analysis.

- The obtained dough will not reach the minimal consistency accepted by the technological line, marked with a safe line on the diagram.

4. DATA STATISTICS AND THE POSSIBILITY OF MULTIPLE RECIPES WRITING FOR KNEADING DIFFERENT TYPES OF DOUGH:

- Based on the recipes which can be introduced into the system, material consumption throughout a working cycle (shift, day, and month) can be evaluated.

5. Dough temperature monitoring and stopping the kneading process for a minimal set consistency value.

Send a request